The Department of Mechanical Engineering was established in the year 1996 and provides an outstanding academic environment complemented by excellence in teaching. The Department offers 4 years undergraduate course (B.E.).

“Strive to thrive for quality manpower who will contribute towards technological development in the field of mechanical engineering and socio-economy”.

dipak.gosai@svmit.ac.in

Ph.D (SVNIT, Surat)

08 September 1997

I.C. Engine, Automobile, Thermal Engineering

vandana.gajjar@svmit.ac.in

M.E (I.C Engine/Auto Engg.)

12 February 2001

I.C. Engine, Automobile, Thermal

bhavesh.patel@svmit.ac.in

M.Tech (Mechanical)

14 February 2000

CAD,CAE, Design & Analysis of Machine Component

umeshjadav73@gmail.com

SSC

03 October 1997

NA

arjunjadav1968@gmail.com

SSC

03 October 1997

NA

hsmehta1977@gmail.com

HSC + ITI

08 February 1999

NA

nishithniraj47@gmail.com

SSC + ITI

16 September 1999

NA

pmmistry1112@gmail.com

SSC

01 August 1997

NA

mbrathod1970@gmail.com

SSC + ITI

01 December 2001

NA

NA

10 + ITI

19 February 2003

NA

harshadbgoswami@gmail.com

SSC

01 February 2013

NA

OBJECTIVES:

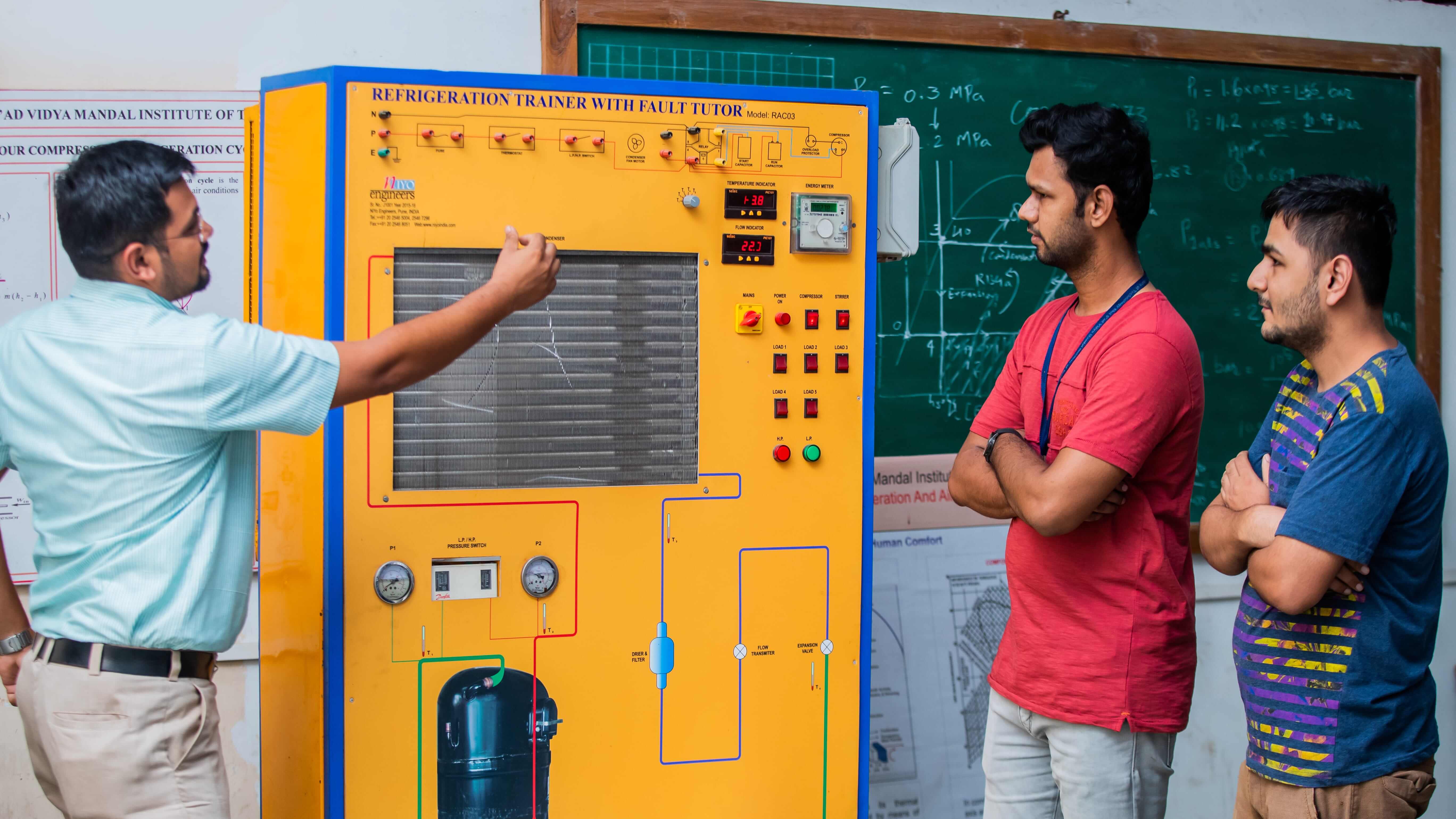

The laboratory is equipped with a wide variety of instructional facilities in the area of refrigeration and air-conditioning. In the refrigeration major equipment includes mechanical heat pump, a single-stage, compression system with capillary and thermostat valve, ice plant, fault tutor, vapour absorption refrigeration system, air-conditioning unit and a collection of other demonstration components.

Objectives of lab

Understand the basic principles of refrigeration and air conditioning.

Analyse air refrigeration systems, vapour compression refrigeration systems, vapour absorption, refrigeration systems, and steam jet refrigeration systems.

Study the psychometric properties of air and utilize the principles of psychometric in the design of air conditioning equipment.

Finally, apply this knowledge for the design of refrigeration equipment’s and air conditioning equipment.

The Department has state-of-the-art infrastructure and facilities bearing Gujarat Technological University (GTU) curriculum. Heat transfer is the transfer of thermal energy from one object or system to another, thus changing the temperature of each object. This process changes the thermal energy of both systems involved until thermal equilibrium is reached.

Thermal energy can be transferred within a given material or from one material to another through conduction. For gases or liquids, heat can be transferred within the material by convection. It can also be transferred indirectly by radiation. More than ten performance practical facilities are available for students.

Objective

The laboratory course is aimed to provide practical exposure to the students with regard to the determination of the amount of heat exchange in various modes of heat transfer, like conduction, convection, and radiation, including condensation & boiling for several geometries and their application

Outcomes

To classify the heat transfer problems and to apply the principles of steady-state one-dimensional heat transfer, extended surface, and unsteady state conduction for commonly encountered Mechanical engineering problems.

To identify the type of convection problems and to apply concepts of natural and forced convection for related problems

To explain various laws of radiation heat transfer and to determine the radiation heat transfer between black and grey surfaces of simple Mechanical systems

To practice LMTD and effectiveness-NTU method for simple heat exchange device

To identify types of boiling and condensation heat transfer process and to use the same to estimate heat transfer coefficient for simple cases.

The Computer-Aided Design (CAD) Lab of the mechanical engineering department is well-equipped with computers with 30 individual workstations & advanced facilities are established. High-end terminals supported by the latest hardware and software. The computers of the CAD laboratory are equipped with software like AutoCAD, Pro-E, Solid works, Hyperworks, ANSYS, MATLAB etc. Advanced mechanical engineering software is procured for making the students globally competitive and industry-ready. At the CAD lab, students get professional training on 2D drafting & 3D modeling of mechanical engineering drawings using the latest version of various software. The student will learn computer-aided design layout and 3D solid modeling definition. Students will also gain the knowledge of design and drafting needed for the mechanical engineering discipline.

The department of mechanical engineering has a

complete range of specialized CAM laboratory with up-to-date equipment for

teaching, learning and research purpose. This laboratory provides an

environment for students to reinforce the fundamental principles of modern

manufacturing systems and apply that knowledge through hands-on training for

the current production technology. Our laboratory functioning with the

following equipments.

I.CNC Turning Center

This

industrial type design slant bed turning centre with 8 station programmable

turret is the ideal machine tool for training our students and this machine can

be compatible with Fanuc control system.

Model: XLTURN

Features:

II. CNC Machining Center

This CNC Milling machine

with an optional 6 station Automatic Tool Changer and this machine can be

compatible with Fanuc control system.

Model: XLMILL

Features:

UID This lab helps students to understand the behavior of fluid under various forces and at different atmospheric conditions, and to select the proper fluid for various applications. This laboratory is scheduled for 4th semester Mechanical engineering students.

The objective of this laboratory is to determine the various parameters related to fluid flow in pipes and in open channels.

| Sr.No. | Name of Students | Event | Platform | Position |

|---|---|---|---|---|

| 1 | KRUPESH KULABKAR | SKIT COMPETITION | Zonal – Level (Youth Fest) | 1 |

| 2 | PRANJUL YADAV (C) PRANAYSINH YADAV (VC) DEEP NIZAMA | KABBADDI | Zonal – Level (Youth Fest) | 1 |

| 3 | PATEL NAJIM ABDUL REHMAN (C) FAYZAN YUSUF CHEPLIN (VC) KAZI AMMAR HUSSAINAHMED | CRICKET | Inter Zonal – Level (Youth Fest) | 1 |

| 4 | DILSAD ANSARI | WESTERN SONG | Zonal – Level (Youth Fest) | 1 |

Jimit patel, Manan Bhatt , Manoj Bhojwani, Swaraj Kadiya - Automated Drainage Response system with Blockage Clearance Facility The team received Grant under SSIP [Student Startup & Innovation Policy] from Gujarat Government: 75000/-

Gohil Daxesh, Gohil Vishal, Gurung Suraj, Raj Tejendrasinh - Hangprinter The team received Grant under SSIP [Student Startup & Innovation Policy] from Gujarat Government: 75000/-

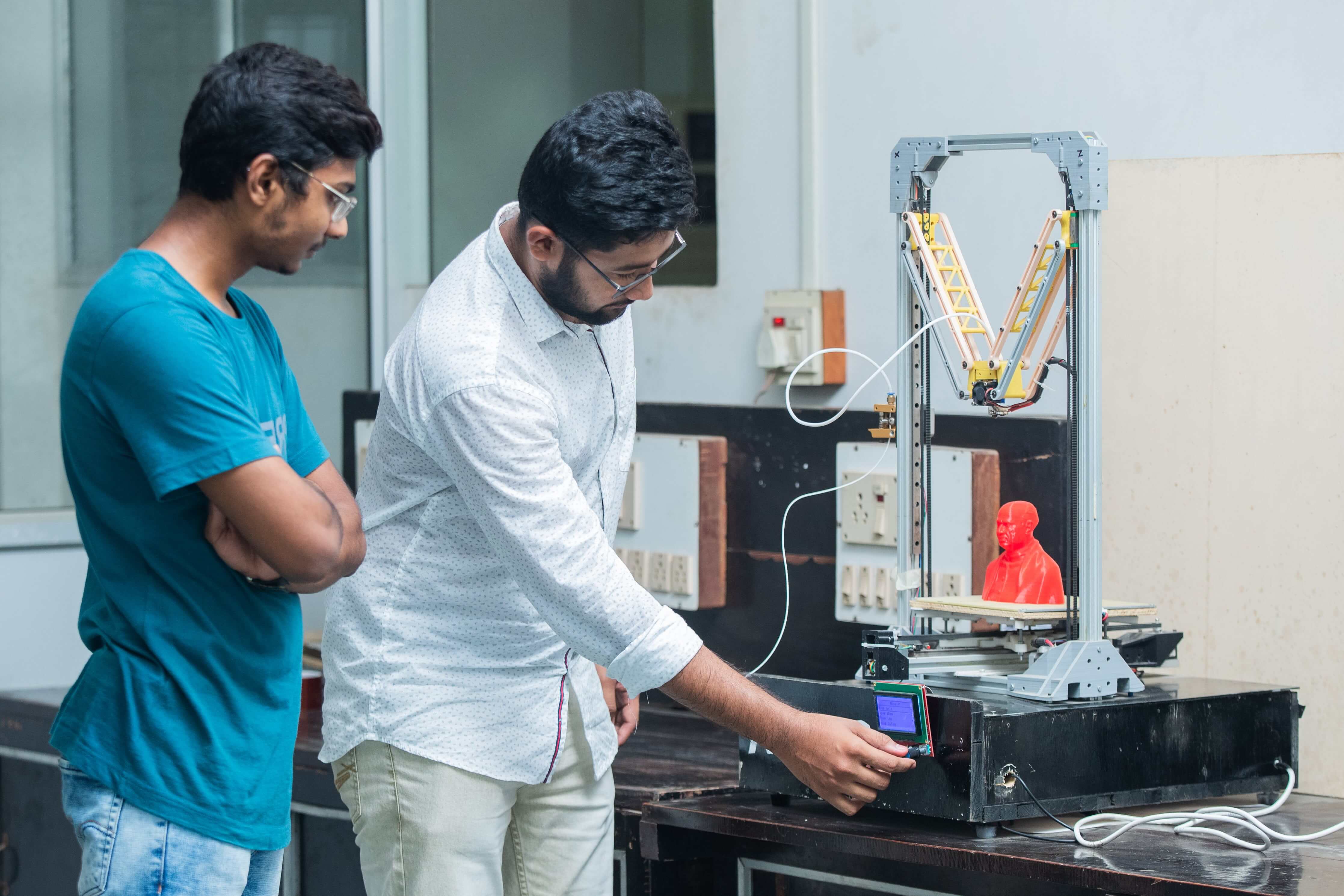

Dilsad Ansari, Abhay Pratap Singh, Dhruvish Shah - CarTa RMC 3D Printer The team received Grant under SSIP [Student Startup & Innovation Policy] from Gujarat Government: 27500/-

Krupesh Kulabkar, Samarth Gandhi, Jay Vanza, Yash Patel, Amartya Mishra - CONSTRUCTION 4.0 The team received Grant under SSIP [Student Startup & Innovation Policy] from Gujarat Government: 50000/-

Krupesh Kulabkar, Deep Patel - Project Grant for Production of electricity from Urine under the guidance of Dr. Nirali Gondaliya, Name of Funding Organization: SOIC (students open innovation challenge)

Dhrumilkumar Patel, Dhaval subhashbhai Patel, Mihir Bipinbhai Patel, Rahul Manohar Patil - ORTHO 3D (Customized 3D Printed Below the-Knee Prosthetic Leg) The team received Grant under SSIP [Student Startup & Innovation Policy] from Gujarat Government: 27500/-

Dilsad Ansari - Dilsad Ansari secured Admission in IIT ROORKEE with a GATE score of 600.

Semester 3 :

| Sr.No. | Name of Students | Enroll No. | SPI |

|---|---|---|---|

| 1 | PATEL KARAN MANOJBHAI | 190450119007 | 7.39 |

| 2 | KAYASTH KRUTARTH AJAYBHAI | 200450119503 | 6.83 |

| 3 | PATEL ISHANG MANOJBHAI | 190450119006 | 6.66 |

| 4 | ASTIK JUGAL MUKESH | 190450119002 | 6.58 |

| 5 | VASAVA JAY SANJAYKUMAR | 200450119523 | 6.43 |

Semester 4 :

| Sr.No. | Name of Students | Enroll No. | SPI |

|---|---|---|---|

| 1 | PATEL ISHANG MANOJBHAI | 1904511 | 8.30 |

| 2 | SINDHA MAHMMAD SAHID SALIMBHAI | 2004511 | 8.13 |

| 3 | PARMAR JAYPALSINH DHIRENDRASINH | 2004511 | 7.96 |

| 4 | VASAVA JAY SANJAYKUMAR | 2004511 | 7.74 |

Semester 5 :

| Sr.No. | Name of Students | Enroll No. | SPI |

|---|---|---|---|

| 1 | DAS MUKUL GANESH | 180450119002 | 8.57 |

| 2 | SHARMA ARPIT SHRIKRISHAN | 180450119012 | 8.61 |

| 3 | MUSAWALA JENISH JAYESHKUMAR | 190453119007 | 7.51 |

| 4 | PATHAN FARHAN TUFELAHAMED | 190453119026 | 7.56 |

| 5 | SONI VIRAJKUMAR ASHOKKUMAR | 190453119014 | 7.43 |

Semester 6 :

| Sr.No. | Name of Students | Enroll No. | SPI |

|---|---|---|---|

| 1 | SHARMA ARPIT SHRIKRISHAN | 180450119012 | 9.70 |

| 2 | DAS MUKUL GANESH | 180450119002 | 9.43 |

| 3 | PATHAN FARHAN TUFELAHAMED | 190453119026 | 8.29 |

| 4 | MUSAWALA JENISH JAYESHKUMAR | 190453119007 | 8.24 |

Semester 7 :

| Sr.No. | Name of Students | Enroll No. | SPI |

|---|---|---|---|

| 1 | PIPROTAR JAYRAJ DEVABHAI | 170450119041 | 9.10 |

| 2 | SINGH ANIKESH MANOJKUMAR | 170450119052 | 8.93 |

| 3 | CHAURASIYA ANKIT UMENDRA | 180453119009 | 8.97 |

| 4 | GUPTA KARAN VINAYKUMAR | 170450119015 | 9.13 |

| 5 | SHAH SHERILKUMAR SUNILBHAI | 170450119048 | 8.97 |

Semester 8 :

| Sr.No. | Name of Students | Enroll No. | SPI |

|---|---|---|---|

| 1 | PIPROTAR JAYRAJ DEVABHAI | 170450119041 | 9.68 |

| 2 | SINGH ANIKESH MANOJKUMAR | 170450119052 | 9.84 |

| 3 | CHAURASIYA ANKIT UMENDRA | 180453119009 | 9.84 |

| 4 | GUPTA KARAN VINAYKUMAR | 170450119015 | 9.80 |

| 5 | SHAH SHERILKUMAR SUNILBHAI | 170450119048 | 9.52 |

Badische Anilin und Soda Fabrik

Eleation

Collabera

Godrej & Boyce Mfg Co Ltd

Ductofab Systems Pvt. Ltd.

Placement 2024 - 2025 :

Placement 2023 - 2024 :

Placement 2022 - 2023 :

Placement 2021 - 2022 :

Placement 2020 - 2021 :

| Sr.No. | Name of Students | Name of Comppany | Company Location |

|---|---|---|---|

| 1 | SHERIL SHAH | Badische Anilin und Soda Fabrik | DAHEJ |

| 2 | KRUPESH KULABKAR | Gulbrandsen Technology Pvt Ltd | Jhagadia |

| 3 | ANKIT CHAURASIYA | Galaxy Surfactant Limited | Jhagadia |

Placement 2019 - 2020 :

| Sr.No. | Name of Students | Name of Comppany | Company Location |

|---|---|---|---|

| 1 | PATEL DIVYESHKUMAR VIJAYKUMAR | Eleation | PUNE |

| 2 | SINGH PRANJUL OMSHANKAR | Collabera | VADODARA |

| 3 | MAURYA MANISHKUMAR MADHAV SHARAN | Godrej & Boyce Mfg Co Ltd | BHARUCH |

| 4 | DIDWANIYA KULDEEP BANSILAL | Ductofab Systems Pvt. Ltd. | VAPI |

| 5 | SINGH LAV AJAY SINGH | Adroit Consultants | BHARUCH |

| 6 | BORSE SUVARNA SANTOSH | APPL | BHARUCH |

| 7 | CHAUHAN HARSHRAJ BHIKHABHAI | Rallis India Ltd | BHARUCH |

| 8 | TAILOR JAIMINI SHAILESHBHAI | APPL | BHARUCH |

| 9 | SONI NISARG PRAKASHKUMAR | Voltamp Transformer Ltd | VADODARA |

| 10 | Thakur Vishal Sandeep | UPL | ANKLESHWAR |

| 11 | SURTI MOHMADSAJID ABDULSAMAD | Adroit Consultants | BHARUCH |

| 12 | PARMAR NISHANTBHAI PRAVINBHAI | Advent Envirocare Technology Pvt. Ltd. | AHMEDABAD |

| 13 | Dharmik Thummar | Yantrah Edutech | SURAT |

| 14 | PATEL MONIL SHASHIKANT | APPL | BHARUCH |

| 15 | SURAJ GURUNG | Engineering Technique | Vadodara |

| 16 | SINGH LAV AJAY SINGH | APPL | Dahej |

| 17 | PATEL MONIL SHASHIKANT | APPL | Dahej |

| 18 | MODI DHAVNIL MAHESHBHAI | GNFC Ltd. | Bharuch |

| 19 | PATEL PARTH JITENDRAKUMAR | GNFC Ltd. | Bharuch |

| 20 | PATEL YASHKUMAR UTTAMBHAI | GNFC Ltd. | Bharuch |

| 21 | PUNEET VISHVAKARMA | GNFC Ltd. | Bharuch |

| 22 | SOHAM INDRAVADAN MAKWANA | GNFC Ltd. | Bharuch |

| 23 | RUPAPARA SAGAR | GNFC Ltd. | Bharuch |

A four-day " Fusion 360 " workshop was organized by Mechanical Engineering Department. Students explored the new features of 3D part modeling.

Webinar on "Climate change and best practices for energy conservation"

webinar on "Industry 4.0"

Webinar on "Solidworks for 3D Modelling"

Webinar on "Awareness and Career Prospects in the Indian Air Force" is arranged on 18th June 2021. Speaker: Wing Commander Sudhir Kumar Sridharan, Aeronautical Engineer (Electronics). Airforce Station Vadodara

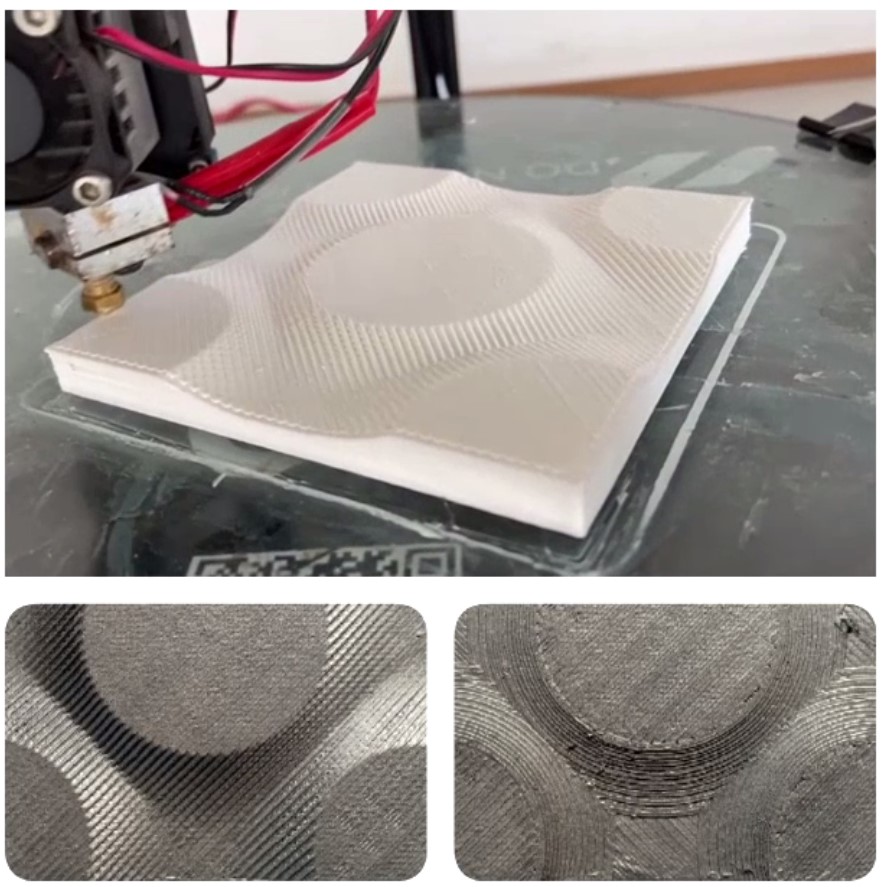

A 3D Printed Memento (Designed and Printed in AM & RE Lab_SVMIT) was given to Shri Morari Bapu at a National Seminar on "Raghuveer Chaudhari Vishesh"

Seminar on 3D Printing by US INSTITUTE of 3D Printing !!

On 20th Anniversary of Kargil_Vijay_Diwas, Students of Mechanical Engineering Department visits Air Force Station, Vadodara.

Seminar on "Career opportunity in INDIAN AIR FORCE" conducted by AirForce Personals at SVMIT, Bharuch !!