The Department of Chemical Engineering was established in the year 1996 and provides an outstanding academic environment complemented by excellence in teaching. The Department offers 4 years undergraduate course (B.E.).

To provide technical education of highest quality for creating highly competent Chemical Engineers. To also inculcate moral values among Chemical Engineering students and make ethically strong professionals in Chemical Engineering field. To develop various entrepreneurial abilities among students for making them future entrepreneurs who will accept new challenges coming their way in this field.

Our efforts are to develop quality technical manpower through interactive communication, short term training program,seminars, group discussions etc.

Our strength is to provide vigorous class room instructions and laboratory experiences using modern equipment and computer based broad insight to develop core competences.

Our endeavor is to impart in depth knowledge by initiating collaborative real life project with nearby industries which in turn increase the capabilities of to meet global challenges.

1. Engineering Knowledge: Apply the knowledge of mathematics, science, engineering fundamentals, and an engineering specialization to the solution of complex engineering problems.

2. Problem Analysis: Identify, formulate, research literature, and analyze complex engineering problems reaching substantiated conclusions using first principles of mathematics, natural sciences, and engineering sciences.

3. Design/development of Solutions: Design solutions for complex engineering problems and design system components or processes that meet t h e specified needs with appropriate consideration for the public health and safety, and the cultural, societal, and environmental considerations.

4. Conduct Investigations of Complex Problems: Use research-based knowledge and research methods including design of experiments, analysis and interpretation of data, and synthesis of the information to provide valid conclusions.

5. Modern Tool usage: Create, select, and apply appropriate techniques, resources, and modern engineering and IT tools including prediction and modelling to complex engineering activities with an understanding of the limitations.

6. The Engineer and Society: Apply reasoning informed by the contextual knowledge to assess societal, health, safety, legal and cultural issues and the consequent responsibilities relevant to the professional engineering practice.

7. Environment and Sustainability: Understand the impact of the professional engineering solutions in societal and environmental contexts, and demonstrate the knowledge of, and need for sustainable development.

8. Ethics: Apply ethical principles and commit to professional ethics and responsibilities and norms of the engineering practice.

9. Individual and Team Work: Function effectively as an individual, and as a member or leader in diverse teams, and in multidisciplinary settings.

10. Communication: Communicate effectively on complex engineering activities with the engineering community and with society at large, such as, being able to comprehend and write effective reports and design documentation, make effective presentations, and give and receive clear instructions.

11. Project Management and Finance: Demonstrate knowledge and understanding of the engineering and management principles and apply these to one’s own work, as a member and leader in a team, to manage projects and in multidisciplinary environments.

12. Life-long Learning: Recognize the need for, and have the preparation and ability to engage in independent and life-long learning in the broadest context of technological change.

pritam.patil@svmit.ac.in

Ph.D.

01 July 2016

Micro fluidics, Nanoparticle/ Nanocomposite Synthesis, Kinetics and Statistical Modeling

dipak.deore@svmit.ac.in

Ph.D.

03 March 2011

Separation Process, Antiscalents

jigar.gurjar@svmit.ac.in

Ph.D.

19 July 2004

Biochemical Engineering, Biofuels, Process Simulation using Aspen Plus, Bioprocess Engineering – Fermentation Process /Wastewater Treatment

satish.chaturvedi@svmit.ac.in

M.E.

03 August 1998

Process Control, Petroleum Refining

palak.trivedi@svmit.ac.in

M.E.

16 July 2007

Process Equipment Design, Chemical Engineering and Thermodynamics

ankur.patel@svmit.ac.in

M.E.

15 June 2012

Polymer Technology, Biopolymers

aesha.mehta@svmit.ac.in

M.E.

01 August 2012

Computer Aided Design & Optimization, Fluid Flow Operation

prince.patel@svmit.ac.in

M.E.

01 July 2023

Transesterification Process, Microwave assisted heating

jnk_md_72@yahoo.co.in

Diploma Chemical Engineering

19 April 1999

NA

jadhavashok0830@gmail.com

10th

15 March 1999

NA

patelmonik.monik@gmail.com

12th

02 February 2013

NA

To learn the various

mechanical operations associated with different solids as well as fluid such as

Jaw Crusher, Ball Mill, Plate and Frame Filter, Cyclone Separator, and Batch

Sedimentation.

List of Practical’s:

1. To determine Rittinger’s constant, Bond’s constant, Kick’s constant ant work index.

2. To determine Nip angle, Reduction ratio, Ribbon factor, Rittinger’s constant,Bond’s constant’ Kick’s constant, kick’s constant, work index as well as theoretical and actual capacity.

3. To determine critical speed, work index, Bond’s law, Rittinger’s law and Kick’s law.

4. To find out surface area, Mass mean diameter, vol. surface mean diameter of particle. To determine the screen efficiency for the given sample.

5.

To measure efficiency for Air inlet condition are 100%, 75%, 50%.

6.

To study the effect of froth floatation.

7. To study the settling characteristics of a given material for different concentrations.

8.

To determine the specific cake resistance using basket centrifuge.

9.

To determine the specific cake resistance using horizontal filter press.

To learn the applied experimentation procedures and operates heat transfer related equipment and systems, study of modes of heat transfer like conduction, convection and radiation and application of these principles using heat exchangers.

To learn the applied experimentation procedures and operates heat transfer related equipment and systems, study of modes of heat transfer like conduction, convection and radiation and application of these principles using heat exchangers.

List of Practical's:

1. Study of composite walls apparatus

2. Study of concentric tube heat exchanger (finned type)

3. Study of concentric tube heat exchanger (plain type)

4. Study of emissivity measurement apparatus

5. Study of heat flow through the lagged pipe

6. Study of heat transfer in natural convection

7. Study of heat transfer in forced convection

8. Study of shell and tube heat exchanger

1

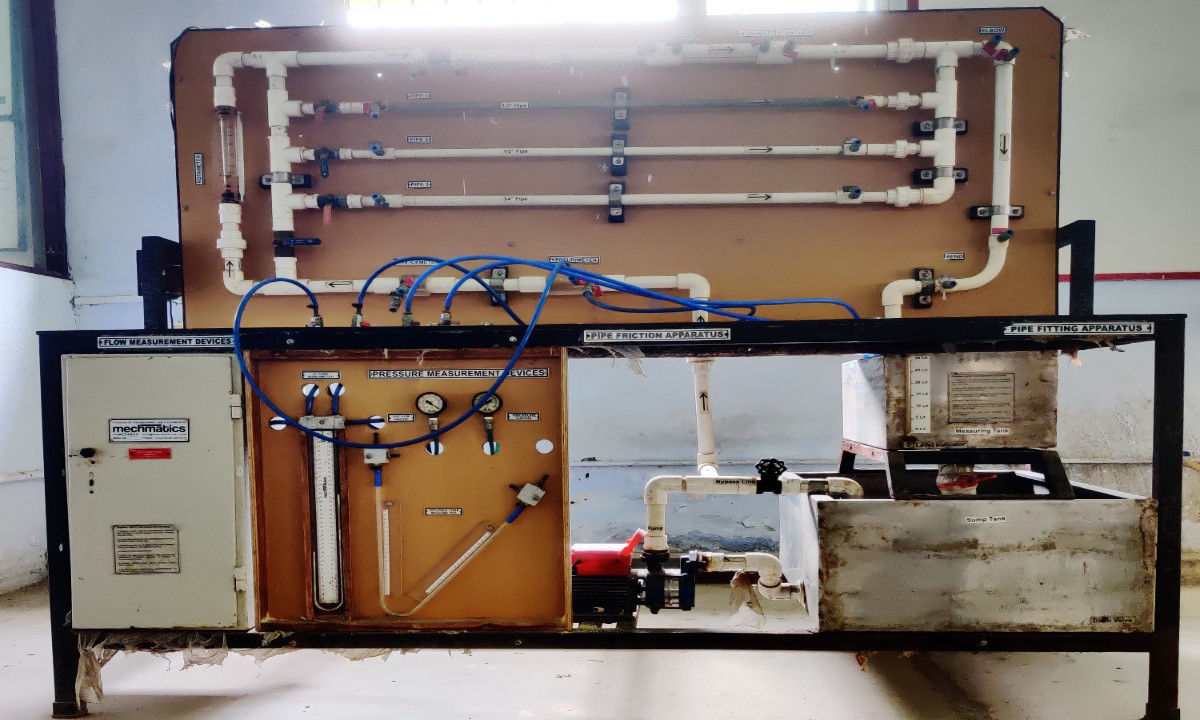

This

Subject is essential for Chemical engineering to know the effect of pressure

and stress of fluid on different bodies. Further, it is useful for students to

know the metering devices for different type of fluids.

This

Subject is essential for Chemical engineering to know the effect of pressure

and stress of fluid on different bodies. Further, it is useful for students to

know the metering devices for different type of fluids.

List of Practical's:

1. To study Pressure and

Pressure measurement devices.

2. To study Rota meter and

obtain its coefficient of discharge.

3. To Calibrate

Venturimeter and obtain its coefficient of discharge.

4. To Calibrate Orifice

meter and obtain its coefficient of discharge.

5. To validate Bernoulli's Theorem

as applied to the flow of water in a tapering circular duct.

6. To calibrate the given

rectangular notch by establishing the relationship between the flow rate and

head over notches.

7. To study the working

principle of Centrifugal pump.

8. To study the working

principle of reciprocating pump.

9. To study the different

types of Valves.

10. To study the blowers

and compressor.

This course provides an introduction to the transient behavior of processes, and the means by which this behavior can be described mathematically, analyzed and controlled.

List

of Practical’s:

1.

To study the response of a first order liquid level system with a step change

in a forcing function using circular hole.

2.

To study the response of a first order liquid level system with a step change

in a forcing function using weir.

3.

To study the response of a second order critically damped system with a step

change in the forcing function.

4.

To study the response of a second order critically damped system with a step

change in the forcing function.

5.

To find out the dynamic response of a second order system to a step change in

the input variable. Also to determine overshoot and decay ratio from the

response and compare with theoretical values.

6.

To determine the relative /absolute density of the given liquid.

7.

To find out the effect of differential gap on the on-off frequency of the

on-off controller.

The

course will provide exposure to advanced separation processes such as membrane

based techniques, chromatographic separation, supercritical fluid extraction

etc.

List of Practical's:

1. Experimental investigation on rejection of salts from water using

flat sheet RO (Reverse osmosis) membrane.

2. To determine separation characteristics of water using flat sheet NF (Nano

filtration) membrane.

3. To determine separation characteristics of water using flat sheet UF

(Ultra filtration) membrane.

4. Experimental investigation on rejection of salts from water using

spiral wound RO(Reverse osmosis) membrane.

5. To determine separation characteristics of water using spiral wound

NF(Nano filtration) membrane.

6. To determine separation characteristics of water using spiral wound

UF(Ultra filtration) membrane.

7. To purify the resorcinol using short path distillation unit.

8. To study Reactive distillation.

9.To study Ion-exchange chromatography.

10.To study Affinity chromatography.

Learn to develop the mathematical models of phenomena involved in various chemical engineering processes and solutions for these models.

List of Practical's:

1. Introduction

of Various Software (Used in Chemical Engineering)

2. Flash

Separator

3. Attainable region for PFR & CSTR for

Van De Vusse reaction system

4. Sequencing of multiple distillation

columns

5. R-Stoic Reactor

6. Design and scheduling of batch process

7. Minimum utility target and pinch point

using temperature interval method

8. Minimum utility target and pinch point

using HCC & GCC method

To learn the applied experimentation procedures and operate mass transfer related equipment and systems, applying the concepts of liquid-vapour, liquid-liquid and solid-liquid phase equilibrium, distillation, rectification, extraction and absorption. This lab gives an overall idea of various Mass Transfer operations used in the industry.

List of Practical's:

1.

To determine Diffusion of Vapour in air using travelling microscope.

2.

To determine the Mass Transfer coefficient of liquid-water and air under

natural conditions

3.

To study the influence of the gas and liquid rates on the rate of Absorption of

carbon dioxide by a caustic soda solution

4.

To prepare ternary equilibrium diagram for Extraction operation

5.

To determine efficiency of extraction of acetic acid from toluene using water

as solvent in three stage extraction operation.

6.

To find out crystal yield with and without seeding

7.

To verify Rayleigh's Equation for Differential Distillation.

8.

To study the distillation with rectification in bubble cap distillation column.

9.

To verify the Equilibrium Relationship for n-Butanol-Water System.

10.

To validate the basic principles of steam distillation.

11.To

verify Freundlich’s Adsorption Isotherm

12.

To study the characteristics of adsorption of moisture on Silica gel.

13.

To study the humidification operation and calculate all psychometric parameters

for air – water system.

14.

To find out the critical moisture content of a given material using rate of

drying curve.

To learn about reaction kinetics for single, multiple, isothermal, non-isothermal reactions and reactor design procedures.

List of Practical’s:

1. To determine the kinetics of the reaction between ethyl acetate and sodium hydroxide at room temperature by integral method of analysis

2. To determine the kinetics of the reaction between ethyl acetate and sodium hydroxide at room temperature by Differential method of analysis

3. To determine the kinetics of the reaction between ethyl acetate and sodium hydroxide at room temperature by Pseudo First order

4. To determine the kinetics of the reaction between ethyl acetate and sodium hydroxide at room temperature by Saponification method of analysis

5. To determine the kinetics of the reaction between ethyl acetate and sodium hydroxide at room temperature by Half Life method of analysis

6. To check the effect of temperature on rate of reaction for the system of Sodium thiosulfate and HCl

7.

To study and analyze (Residence Time Distribution) RTD of packed bed reactor

8.

To study and analyze (Residence Time Distribution) RTD of Spiral Coil reactor

9. To study and analyze (Residence Time Distribution) RTD of single CSTR and CSTR in series and predict the Dispersion Number

To study the fundamental concept of biological systems, bio-chemical engineering, advanced bioprocess engineering, biologically mediated processes and waste treatment.

List of Practical’s:

1.

Introduction to various equipment’s used in Biochemical Practical’s

2.

To determine the Total Carbohydrates in the sample by Anthrone Method

3.

To determine the growth phases of microorganisms

4.

To determine the temperature effect on microorganisms

5.

To determine the effect of pH on growth of microorganisms

6.

To study the media preparation

7.

To estimate the protein content by spectrophotometric assay

8.

To study Thin Layer Chromatography as one of the separation technique used for

separation of biomolecules

9.

To determine the Kla value using sodium sulphite oxidation technique

| Sr.No. | Name of Students | Event | Platform | Position |

|---|---|---|---|---|

| 1 | Mr. Nirmal K. Padhiyar | Kho-Kho | GTU | Selected with 5th Rank |

| 2 | Parth Joshi | Fuzzy logic and its application in process control | M S University | Runner Up |

| 3 | Anurag Rana | IIChE-ARC Quiz Competition | IIChE – Student Chapter (SVMIT) | Winner |

| 4 | Neel Thakker | MIAME | Zonal – Level (Youth Fest) | Winner |

| 5 | Yash Shah | Poster Presentation | SRICT – TECHFEST | Runner Up |

| 6 | Nirmit Thakore | Western Group Song | Youth Festival South Zone XITIJ | Winner |

| 7 | Raghav Dave | Classical Solo TABLA | Zonal Level (Youth Fest) | Winner |

| 8 | Harsh Modi | One act Play | Youth Festival South Zone XITIJ | Winner |

Tejas Girase, Krutik Patel - Project grant for Lab to Pilot scale production of High purity Magnesium Hydroxide under the guidance of Dr. Pritam Patil, Name of Funding Organization: SSIP (students start up and innovation policy)

Harsh Jitendrabhai Mahaliya - Harsh Mahaliya of final year chemical engineering has qualified the GATE 23 examination with score 274(AIR:3381).

Tejas Alekar, Manish Mahajan - Project grant for Dscal-Domestic water softner device under the guidance of Dr. Dipak Deore, Name of Funding Organization: SSIP (students start up and innovation policy)

PATANVADIYA ADITYA, PATEL HENIL, PARMAR RUSHIL , KAYASTH SANKETKUMAR - Chemical Engineering students became winner at 2nd position in category of Large Scale Industries and PSU, and were awarded Rs 35000 cash at Grand Finale of “Smart Gujarat for New India Hackathon 2019” under the mentorship of Dr Jigar Gurjar .

Shreyash Thakar - Project Grant for Plastic Pavers block under the guidance of Dr. Jigar Gurjar and Dr. Nirali Gondaliya, Name of Funding Organization: SSIP (students start up and innovation policy)

Deep Patel, Dev Patel, Dhruv Patel, Viren Parmar, Henil Patel - Project grant for Effective coagulants and flocculants for effluent treatment plants under the guidance of Dr. Dipak Deore, Name of Funding Organization: SSIP (students start up and innovation policy)

Deep Patel, Krupesh Kulabkar - Project Grant for Production of electricity from Urine under the guidance of Dr. Nirali Gondaliya, Name of Funding Organization: SOIC (students open innovation challenge)

Rushil Parmar, Jainish Parmar, Maharshi Shah, Sanket Kayasth - Poster presentation on Treating landfill leachate by electrocoagulation at 15th Annual session of students, Chemical Engineering congress at SRICT, Ankleshwar.

Deep Patel, Dev Patel, Dhruv Patel, Viren Parmar - Poster presentation on Production of Bio-diesel from algae at 15th Annual session of students, Chemical Engineering congress at SRICT, Ankleshwar.

Semester 3 :

| Sr.No. | Name of Students | Enroll No. | SPI |

|---|---|---|---|

| 1 | KHATIK VINIT LAXMANKUMAR | 240453105023 | 8.74 |

| 2 | SHAIKH MOHAMAD HUMZAH MOHAMAD RIYAN | 240453105084 | 8.74 |

| 3 | THAKOR MAHAVIRSINHJI SHATRUJITSINHJI | 240453105094 | 8.35 |

| 4 | MISTRY HARSHKUMAR NAVINKUMAR | 240453105035 | 7.91 |

| 5 | PATEL HUZAIFA NAZIR | 230450105011 | 7.91 |

Semester 4 :

| Sr.No. | Name of Students | Enroll No. | SPI |

|---|---|---|---|

| No Records | |||

Semester 5 :

| Sr.No. | Name of Students | Enroll No. | SPI |

|---|---|---|---|

| 1 | PATEL VEER PADYUMANBHAI | 230453105068 | 8.48 |

| 2 | YADAV SAMARTHSINH JAYDIPSINH | 220450105015 | 8.43 |

| 3 | PADHIYAR NIRMAL KETANBHAI | 230453105040 | 8.39 |

| 4 | KAYASTH NEEL HITESHCHANDRA | 220450105005 | 8.26 |

| 5 | PATEL SAFVAN MOHAMMADSIDDIK | 230453105066 | 8.26 |

Semester 6 :

| Sr.No. | Name of Students | Enroll No. | SPI |

|---|---|---|---|

| No Records | |||

Semester 7 :

| Sr.No. | Name of Students | Enroll No. | SPI |

|---|---|---|---|

| 1 | SHAIKH KAISH AMIRAZAM | 210450105010 | 9.54 |

| 2 | SRIVASTAVA AKSHITKUMAR ARVIND | 210450105033 | 9.08 |

| 3 | PATANVADIYA DIGVIJAYSINH HASMUKHBHAI | 210450105026 | 8.79 |

| 4 | PATEL YAHYA MAHAMMAD ABDULLAH | 210450105034 | 8.38 |

| 5 | Gohel Nirmalkumar Chandubhai | 210450105029 | 8.25 |

Semester 8 :

| Sr.No. | Name of Students | Enroll No. | SPI |

|---|---|---|---|

| No Records | |||

Alembic Pharmaceuticals Ltd

GFL

Galaxy Surfactants Limited

Reliance Industries limited

Apcotex Industries Ltd

Placement 2024 - 2025 :

| Sr.No. | Name of Students | Name of Comppany | Company Location |

|---|---|---|---|

| 1 | Nisha Prashad | Lubrizol Advanced Materials India Pvt. Ltd. ( Lubrizol Corporation) | Dahej |

| 2 | Gohil Kuldeepkumar Kiranbhai | UPL Limited | Ankleshwar |

| 3 | Srivastava Akshitkumar Arvind | UPL Limited | Ankleshwar |

| 4 | Dhruvil Patel | Epigral Limited (MFL) | Dahej |

| 5 | Neel Prajapati | Epigral Limited (MFL) | Dahej |

| 6 | Deep Parmar | Epigral Limited (MFL) | Dahej |

| 7 | Shrimay Hetalkumar Pandya | UPL Limited | Ankleshwar |

| 8 | Patel Fardin Mustak | UPL Limited | Ankleshwar |

| 9 | Dhaval Bhatt | UPL Limited | Ankleshwar |

| 10 | Smit Chandreshkumar Patel | UPL Limited | Ankleshwar |

| 11 | patel Chintan jerambhai | UPL Limited | Ankleshwar |

| 12 | Soni Meet Janakkumar | UPL Limited | Ankleshwar |

| 13 | Soni Meet Janakkumar | UPL Limited | Ankleshwar |

| 14 | Patel Jainam Sanjaykumar | UPL Limited | Ankleshwar |

| 15 | Patel Chintan V. | UPL Limited | Ankleshwar |

| 16 | Taxil Chauhan | UPL Limited | Ankleshwar |

| 17 | Amardeepsingh Jandu | UPL Limited | Ankleshwar |

Placement 2023 - 2024 :

| Sr.No. | Name of Students | Name of Comppany | Company Location |

|---|---|---|---|

| 1 | Sachin Chaubey | Alembic Pharmaceuticals Ltd | Vadodara |

| 2 | Ajmeri Harshkumar Bharatbhai | GFL | Dahej |

| 3 | Mistry Vivek Suhasbhai | Panoli Intermediates | Jhagadia |

| 4 | Vasava Vivek Maheshbhai | Panoli Intermediates | Jhagadia |

| 5 | Yadav Atul Satish | Panoli Intermediates | Jhagadia |

| 6 | Girase Tejas Bhausaheb | Panoli Intermediates | Jhagadia |

| 7 | Kesrola Divyanshi Ajitsinh | GFL | Dahej |

| 8 | Mistry Bhavik Arvindbhai | GFL | Dahej |

| 9 | Chauhan Jinal Vindokumar | GFL | Dahej |

| 10 | Patel Nirajkumar Pankajbhai | GFL | Dahej |

| 11 | Patel Om Pankeshkumar | GFL | Dahej |

| 12 | Vaidya Shubh Shaileshbhai | GFL | Dahej |

| 13 | Gohil Jinalben Natwarbhai | GFL | Dahej |

| 14 | Mistry Dhruvkumar Meeneshbhai | Epigral Limited (MFL) | Dahej |

Placement 2022 - 2023 :

| Sr.No. | Name of Students | Name of Comppany | Company Location |

|---|---|---|---|

| 1 | Het Patel (Internship/GET) | Deccan Fine Chemicals | Ankleshwar |

| 2 | Parthkumar M Patel (Internship/GET) | Deccan Fine Chemicals | Ankleshwar |

| 3 | Omkar Jinvndhar Patil(Internship/GET) | Deccan Fine Chemicals | Ankleshwar |

| 4 | Joshi Falgun Dharmeshbhai (Internship/GET) | Deccan Fine Chemicals | Ankleshwar |

| 5 | Akash Tribhuvan (Internship/GET) | Deccan Fine Chemicals | Ankleshwar |

| 6 | Soni Harsh Vinodbhai (Internship/GET) | Deccan Fine Chemicals | Ankleshwar |

| 7 | Deep Patel | Reliance Industries limited | Jamnagar |

| 8 | Patel Karan | Reliance Industries limited | Jamnagar |

| 9 | Patel Parth | Reliance Industries limited | Jamnagar |

| 10 | Lalit U Pandey | Gujarat Fluorochemicals Ltd | Dahej |

| 11 | Vraj Janakbhai Pandya | Gujarat Fluorochemicals Ltd | Dahej |

| 12 | Patel Tapankumar Premendrakumar | Firmenich Aromatics production India Pvt Ltd | Dahej |

| 13 | Soni Harsh Vinodbhai | Meghmani Finechem Limited | Dahej |

| 14 | Dalal Gautam Devangbhai | Meghmani Finechem Limited | Dahej |

| 15 | Kanitkar Bharat Milind | Meghmani Finechem Limited | Dahej |

| 16 | Mistry Jaimin Vinubhai | Meghmani Finechem Limited | Dahej |

| 17 | Ambalia Devrajsinh Jitendrasinh | Meghmani Finechem Limited | Dahej |

| 18 | Ayushkumar Shailesh Chauhan | Nitrex Chemicals India Ltd | Jhagadia |

| 19 | Maharshi Naishedhbhai Patel | Nitrex Chemicals India Ltd | Jhagadia |

| 20 | Mitanshu Bhupendrabhai Patel | Nitrex Chemicals India Ltd | Jhagadia |

| 21 | Anuragsinh Dharmendrasinh Devadhara | Nitrex Chemicals India Ltd | Jhagadia |

| 22 | Priyanshu Kamleshkumar Rana | Nitrex Chemicals India Ltd | Jhagadia |

| 23 | Smit Prakashbhai Modi | Nitrex Chemicals India Ltd | Jhagadia |

| 24 | Harsh Jitendrabhai Mahaliya | Nitrex Chemicals India Ltd | Jhagadia |

| 25 | Bhargav Hasmukhbhai Parmar | Nitrex Chemicals India Ltd | Jhagadia |

| 26 | Dhruv Chandreshbhai Gajjar | Nitrex Chemicals India Ltd | Jhagadia |

| 27 | Vipul Vijay Varma | Nitrex Chemicals India Ltd | Jhagadia |

| 28 | Manish Kanaksinh Padhiyar | Nitrex Chemicals India Ltd | Jhagadia |

Placement 2021 - 2022 :

| Sr.No. | Name of Students | Name of Comppany | Company Location |

|---|---|---|---|

| 1 | Sunva Digvijaysinh Arvindsinh | Reliance Industries limited | Jamnagar |

| 2 | Solanki Harsh Ashokbhai | Galaxy Surfactants Limited | Jhagadia |

| 3 | Patel MusaddikAli SadikAli | Galaxy Surfactants Limited | Jhagadia |

| 4 | Sony Antony | GNFC | Bharuch |

| 5 | Verma Akhilesh Banshraj | GNFC | Bharuch |

| 6 | Patel Jugal Kumar Harshadbhai | Gujarat Fluorochemicals Ltd | Dahej |

| 7 | Tailor Shubham Rajkumar | Gujarat Fluorochemicals Ltd | Dahej |

| 8 | Patel Yashkumar Sanjeevkumar | Gujarat Fluorochemicals Ltd | Dahej |

| 9 | Patel Vedant | Gujarat Fluorochemicals Ltd | Dahej |

| 10 | Rana Nirlay Shaileshbhai | Gujarat Fluorochemicals Ltd | Dahej |

| 11 | Bhatt Rutvi Vimalkumar | Gujarat Fluorochemicals Ltd | Dahej |

| 12 | Dodiya Yuvrajsinh Gajendrasinh | Nitrex India Pvt Ltd | Jhagadia |

| 13 | Yadav Brijkishor Suraj | Nitrex India Pvt Ltd | Jhagadia |

| 14 | Thakar Parth Mukundrai | Nitrex India Pvt Ltd | Jhagadia |

| 15 | Yadav Harmitsinh Hitendrasing | Deccan Fine Chem.Pvt Ltd | Ankleshwar |

| 16 | Argade Kunalkumar pramodrao | Deccan Fine Chem.Pvt Ltd | Ankleshwar |

| 17 | Multani Tofik Salimbhai | Raksh Pharma | Dahej |

| 18 | Patel Tejaskumar Yogeshkumar | Raksh Pharma | Dahej |

| 19 | Patel Dhavalkumar Devendrabhai | UPL-I | Ankleshwar |

| 20 | Mehta Priyank Brijesh | Bharat Rasayan Limited | Dahej |

| 21 | Gujjar Abhishek Kamleshbhai | Nitrex India Pvt Ltd | Jhagadia |

Placement 2020 - 2021 :

| Sr.No. | Name of Students | Name of Comppany | Company Location |

|---|---|---|---|

| 1 | Sharma Ashish | Galaxy Surfactants Limited | Jhagadia |

| 2 | Patel Dev Urveshkumar | Gulbrandsen Technologies Pvt Ltd | Jhagadia |

| 3 | Patel Yagnesh Dhirajbhai | Nitrex India Pvt Ltd | Jhagadia |

| 4 | Parmar Rushil Vasantlal | Nitrex India Pvt Ltd | Jhagadia |

| 5 | Patel Dhruv Mukeshbhai | Raksh Pharma | Dahej |

| 6 | Patel Yashkumar Pravinbhai | Raksh Pharma | Dahej |

| 7 | Parmar Jainish DipakKumar | TOYO Ink Pvt. Ltd | Dahej |

| 8 | Patel Viren Bhupendrasinh | Lewens Labs | Dahej |

| 9 | Dave Vinit Ghanshyambhai | GNFC | Bharuch |

| 10 | Patel Faizan Daud | GNFC | Bharuch |

| 11 | Peerzada Azeem Zahid | GNFC | Bharuch |

| 12 | Dhavalkumar Ganpatbhai Parmar | GNFC | Bharuch |

| 13 | Saparia Sagarkumar Pareshbhai | GNFC | Bharuch |

| 14 | Gohil Jaiminee Laxmanbhai | GNFC | Bharuch |

| 15 | Patel Mohammedayaj R | GNFC | Bharuch |

| 16 | Modi Rhutik | GNFC | Bharuch |

| 17 | Modi Yash Dineshchandra | GNFC | Bharuch |

| 18 | Khotiya Mohammed Taki Sikander | GNFC | Bharuch |

| 19 | Vaghela Rahul Manharbhai | GNFC | Bharuch |

Placement 2019 - 2020 :

| Sr.No. | Name of Students | Name of Comppany | Company Location |

|---|---|---|---|

| 1 | Bharthnia Dhavalraj Indrasinh | Apcotex Industries Ltd | Valia |

| 2 | Solanki Yash | Ion Exchange India Ltd | Ankleshwar |

| 3 | Yadav Jitesh | Zydus Cadila | Ankleshwar |

| 4 | Patel Dhruvalkumar Pareshbhai | Sunpharma | Dahej |

| 5 | Modi Rushikkumar Shaileshkumar | Sunpharma | Panoli |

| 6 | Modi Nisarg Jatinkumar | ELANTAS Beck India Ltd | Ankleshwar |

| 7 | Modi Dhruvil | Deccan Fine Chem.Pvt Ltd | Ankleshwar |

| 8 | Parmar Ravindrasinh Narendrasinh | Deccan Fine Chem.Pvt Ltd | Ankleshwar |

| 9 | Shah Maharshi AnilKumar | Nitrex India Pvt Ltd | Jhagadia |

| 10 | Trivedi Trumulkumar Chetankumar | Nitrex India Pvt Ltd | Jhagadia |

| 11 | Patel Hajimabanu | GNFC | Bharuch |

| 12 | Sharma Rahul Rajendraprasad | Nitrex India Pvt Ltd | Jhagadia |

| 13 | Patel Amish | Nitrex India Pvt Ltd | Jhagadia |

| 14 | Bhatt Ronakkumar Janakkumar | GNFC | Bharuch |

| 15 | Malek Mo Irfan Abdul Aziz | GNFC | Bharuch |

| 16 | Ganja Raiyan Farukbhai Musabhai | GNFC | Bharuch |

| 17 | Patel Mayur Ranjitbhai | GNFC | Bharuch |

| 18 | Patel Neelkumar Rajendrabhai | GNFC | Bharuch |

| 19 | Patel Pintubhai Shravanbhai | GNFC | Bharuch |

| 20 | Patil Vaidehi | GNFC | Bharuch |

| 21 | Rana Urvesh Dharmendrabhai | GNFC | Bharuch |

| 22 | Shaikh Mohammednaeem Iqbal | GNFC | Bharuch |

| 23 | Solanki Rikul Thakorbhai | GNFC | Bharuch |

| 24 | Varudi Aadil Abdulrashid | GNFC | Bharuch |

| 25 | Sheth Mahmedjuned Iqbal | GNFC | Bharuch |

| 26 | Shaikh Mohamed Salman Akhtar | GNFC | Bharuch |

| 27 | Solanki Nikunj | Valia Polytechnic college | Valia |

| 28 | Patel Mohammadrehan S | GAIL India | Bharuch |

| 29 | Prasad Amit | Sajjan India Ltd | Ankleshwar |

| 30 | Shah Meet | Deepak Nitrite Ltd | Dahej |

| 31 | Jadav Gaurav | CS Performance Chemicals Pvt Ltd | Dahej |

| Sr.No. | Event | Date |

|---|---|---|

| 1 | Expert Talk: Reactive Distillation | 23 , Feb , 2023 |

| 2 | Expert Talk: Carrier guidance for chemical engineering students | 09 , Feb , 2023 |

| 3 | Expert Talk: Distillation a unit operation from industry perspective | 15 , Sep , 2022 |

| 4 | Expert Talk: Diversification of chemical field | 15 , Sep , 2022 |

| 5 | Expert Talk: If opportunity doesn't knock build a door- Entrepreneurship | 15 , Sep , 2022 |

| 6 | Expert talk: Automation in Chemical Industry | 15 , Feb , 2022 |

| 7 | Expert talk: Heat Exchanger Design | 06 , Feb , 2022 |

| 8 | Live talk: overview of softwares for chemical engineering | 05 , Mar , 2021 |

| 9 | Expert talk: Climate change and best practices for energy conservation | 26 , Sep , 2021 |

| 10 | Expert talk: Online sealing and hot tapping in hydrocarbon lines without taking shutdown | 25 , Feb , 2021 |

| 11 | Expert talk: Water and Waste water Treatment | 24 , Sep , 2021 |

| 12 | Expert talk: Organizing the manufacturing processes for best utility and economics | 09 , Oct , 2020 |

| 13 | Expert talk: Instrumentation and control | 07 , Oct , 2020 |

| 14 | Expert talk: Campus to Corporate | 20 , Sep , 2019 |

| 15 | Expert talk: Petrochemical Industries: Boon to society | 30 , Aug , 2019 |

| 16 | Expert talk : Introduction to Plant design and Project engineering | 25 , Jul , 2019 |

An Industrial visit conducted at GNFC-Bharuch for 3rd year chemical engineering students of SVMIT on 21st march 2025.

An Industrial visit conducted at Ankleshwar Research & Analytical Infrastructure Ltd - Ankleshwar for 2nd year chemical engineering students of SVMIT on 1st February 2025

A live expert talk by Mr. Manish Rai (Manager, Tech. Services-GNFC) was organized by department of chemical engineering and IICHE student chapter for Chemical Engineering students of SVMIT on 30th January 2025

An expert lecture conducted by Mr. M.R. Havaldar (GNFC) on “Process Safety Management” for 2nd year Chemical Engineering Students on 7th October 2024.

An industrial visit for final year chemical engineering students was conducted on 12th September 2024 at vihita chemical pvt limited-Ankleshwar

"Expert Session on Various Competitive Exams for 2nd Year Chemical Engineering Students conducted by acumen GATE ACADEMY on 9th September 2024"

An expert lecture conducted by Mr. Nishant Raval (manager-GNFC) on Heat Exchangers and Cooling Tower Operations to Chemical Engineering Students on 30th August 2024"

Chemical Engineering Department celebrated Merit Award Function for meritorious students of all four years on 16th April 2024.

An Industrial visit conducted at Navadia Industries - Ankleshwar for 3rd year chemical engineering students of SVMIT on 13th March 2024.

A Virtual Expert Lecture delivered by Mr. Chandrakant Bhakta (GM-GNFC) on "Chemical Industry Growth Globally" on 12th September 2023

An Expert Talk Delivered by Shri P. M. Kapadia, GNFC on the topic of 'Pumps' on 5th april 2023.

An Industrial Visit was organized for 2nd and 3rd yr. chemical engineering students on 31st March 2023 @ BEIL, Ankaleshwar.

An Expert Talk Delivered by Dr. Meghal Desai, Associate Professor & HOD, Chemical Engineering Dept., SVNIT, Surat (Our Alumini) on the topic of 'Reactive Distillation' on 23rd February 2023

An Expert Talk Delivered by Mr. Nilesh More on the topic of 'Career guidance for Chemical Engineering students' on 9th February 2023

An Industrial visit conducted at GNFC-Bharuch for 3rd year chemical engineering students of SVMIT on 17th October 2023.

An Industrial Visit was organized for 3rd yr. chemical engineering students on 1st October 2022 @ GNFC, Bharuch.

Engineers day celebration-15th sep. 2022

Merit Award Function 2022: 8th April 2022

An Industry Visit was organized for Third Year Students on 29th March 2022 @Vihita Chem Private Limited

Quiz Competition: 25th March 2022

Internal Hackathon 2022(Hardware Edition) on 21-22, March 2022

An Industry Visit was organized for Final Year Students on 9th Oct. 2021 @ Lupin Ltd. Ankleshwar.

An Industry Visit was organized for Third Year Students on 27th and 28th Sep. 2021 @Vihita Chem Private Limited

Virtual Alumni Meet 2022

Techfest-chemical

Workshop on I2E conducted by GIC

IIChE Induction Program

Merit Award Function for 2nd , 3rd and 4th Year Students

Industry – Institute Interaction Week by IIChE student chapter

Technical Quiz Competition- IIChE

Go-Green Event- 2016

Personality Development Seminar by JCI, Bharuch